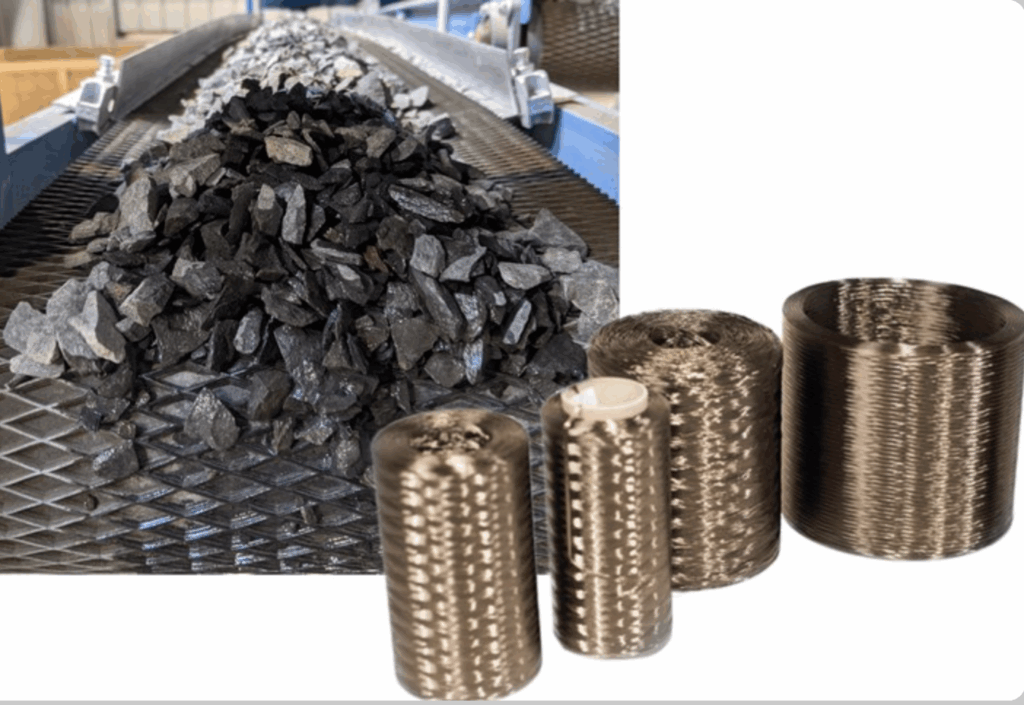

In the quest for sustainable materials that don’t compromise on performance, basalt fibers are emerging as a game-changer in the world of composites. Derived from volcanic basalt rock, these fibers are melted at high temperatures and spun into fine threads, offering a natural alternative to traditional reinforcements like glass or carbon fibers. Unlike synthetic options, basalt fibers require no chemical additives during production, making them eco-friendly and recyclable. As industries like renewable energy push for greener solutions—think wind and tidal turbine blades—basalt fiber composites are gaining traction for their impressive mechanical properties and resistance to harsh environments. This article dives into why basalt fibers matter, their key benefits, and how they hold up under challenging conditions like moisture exposure.

Table of Contents

Key Advantages:

Some of the top benefits that make basalt fiber a preferred choice over conventional reinforcements:

Versatile Resin Compatibility Bonds seamlessly with epoxy, polyester, vinyl ester, and phenolic resins—suitable for hand lay-up, infusion, pultrusion, and filament winding.

100% Natural & Eco-Friendly Sourced directly from abundant volcanic rock, basalt fiber production consumes less energy than E-glass and leaves zero toxic waste.

Exceptional Mechanical Performance Tensile strength comparable to E-glass (up to 4,800 MPa in filament form), with a strain-to-failure of 3.15% and density of 2.8 g/cm³—ideal for lightweight, high-strength applications.

Superior Thermal Resistance Withstands temperatures up to 650–700°C, non-combustible, and maintains stability in extreme heat—perfect for fire-safe structures.

Excellent Chemical & Corrosion Resistance Naturally immune to rust, alkali, and acid attack—outperforming E-glass in harsh marine or chemical environments.

Outstanding Acoustic & Thermal Insulation Provides superior sound dampening and heat insulation, enhancing energy efficiency in buildings and vehicles.

Fully Recyclable & Cost-Effective Can be crushed and reused without losing integrity, offering a lower lifecycle cost and higher sustainability score than carbon fiber.

Basalt Fiber vs Traditional Reinforcements: A Quick Comparison

| Property | Basalt Fiber | E-Glass Fiber | Carbon Fiber |

|---|---|---|---|

| Raw Material | Volcanic rock | Silica sand + lime | PAN/oil-based |

| Additives Required | None | Yes (boron, etc.) | Yes |

| Energy Consumption | Low | Medium | Very High |

| Recyclability | Yes | Limited | No |

| Corrosion Resistance | Excellent | Moderate | Excellent |

| Cost per Performance | High | Medium | Low |

| Environmental Impact | Minimal | Moderate | High |

Applications of Basalt Fiber in Modern Industries

Thanks to its balanced profile, basalt fiber is being adopted across diverse sectors:

Sporting Goods → Bicycle frames, hockey sticks, and fishing rods

Wind & Tidal Energy → Turbine blades using non-crimp fabric (NCF) basalt/epoxy composites

Automotive → Lightweight body panels, brake pads, and exhaust systems

Construction → Rebar, mesh, and panels for seismic-resistant, corrosion-free structures

Marine → Boat hulls, docks, and offshore platforms

Aerospace & Defense → Heat shields, ballistic panels, and structural components

Conclusion: The Future Is Basalt

Basalt fiber isn’t just another reinforcement—it’s a sustainable evolution in composite technology. With mechanical properties rivaling synthetic fibers, zero harmful additives, and full recyclability, it aligns perfectly with global demands for greener, stronger, and smarter materials.

Whether you’re designing next-generation wind turbines, eco-friendly infrastructure, or high-performance consumer products, basalt fiber offers the strength of tradition and the conscience of innovation.